Accurate drywall takeoff is a crucial step in construction estimating. Whether you’re a contractor, builder, or estimator, getting the right measurements ensures that you order the correct amount of materials, avoid waste, and stay within budget. Drywall takeoff involves calculating the number of drywall sheets, joint compound, screws, and other materials needed for a project. If done correctly, it can save time and money and prevent costly mistakes on-site.

In this guide, we’ll walk you through the step-by-step process of performing a drywall takeoff, from measuring walls and ceilings to accounting for waste and openings like doors and windows. By the end, you’ll have a clear understanding of how to create an accurate drywall estimate for any project.

What You’ll Learn

- Why a precise drywall takeoff is critical for budget control, minimal waste and successful bids.

- A structured, step-by-step process: from scope definition through to material, labour and finishing allowances.

- Practical formulas, software tools and “pro tips” to improve your accuracy.

- Common mistakes to avoid and a downloadable checklist to streamline your workflow.

Steps Of How To Do Takeoff For Drywall

Before estimation, it is essential to have a clear understanding of the entire process of how to do a takeoff for drywall accurately. An accurate drywall is an indicator of smoother operations, better financial management, and overall project success. Let’s outline the steps to measure the takeoff for drywall:

Understanding The Scope Of The Project

Determine the parameters of the project deeply that set the foundation to initiate the project. It includes reviewing the requirements to install a drywall by architectural drawings and blueprints. Typically, the estimators identify the type of wall and measure the dimensions of the wall to plan the material and labor costs from the initial to the final step. A well-determined scope ensures the accuracy and efficiency of the estimate.

Review Construction Documents

The construction documents guide the feasibility of the project by thoroughly reviewing the deliverables of the project. It dictates the following aspects to create a meticulous estimate:

- Outlining contractual agreement in the bid document

- Structural schematics to reflect the dimensions of drywall

- Standard instructions for drywall installation

- Materials and equipment to carry out the installation of drywall.

Access Wall Conditions

Examine the conditions of drywall to perform efficient takeoff to ensure the profitability of the project. It gives you an idea about the quality and quantity of resources for the project. The following are the checkpoints to assess it:

- The notable defects in the wall surface are dips, bows, and bumps.

- Notice the existing state of the wall _ it can be new construction, a remodeled wall, or an aged wall.

- The type of work done, such as concrete, brick or wood wall

- Find out the potential damaging indicators like moisture and dampness.

You might like this too: How to Do a Masonry Estimate: A Step-by-Step Guide

Identify Key Drywall Components

When it comes to drywall installation, some key components are necessary to ensure the durability and longevity of the construction process. It includes:

- Drywall sheet: A prime component to create a seamless surface in drywall installation

- Tape: A targeted material to seal the joints between drywall sheets

- Cornes bead: A strengthening component to cover the exposed surfaces it corners

- Joint compounds: Purposed to fill the seam and cover fasteners to design a smooth surface

- Drywall screws: Screws are used to secure the drywall panels

Count Wall Openings

It refers to checking out the areas where drywall installation is not required, such as doors, windows, vents, electrical switches and outlets and any other opening to order the exact amount of material. Utilize the advanced construction software to count wall openings such as bluebeam Revu, ProEst, CostX, PlanSwift and many more to minimize the manual errors. Construction firms perform digital takeoff to steer the estimating process for stability and profitability.

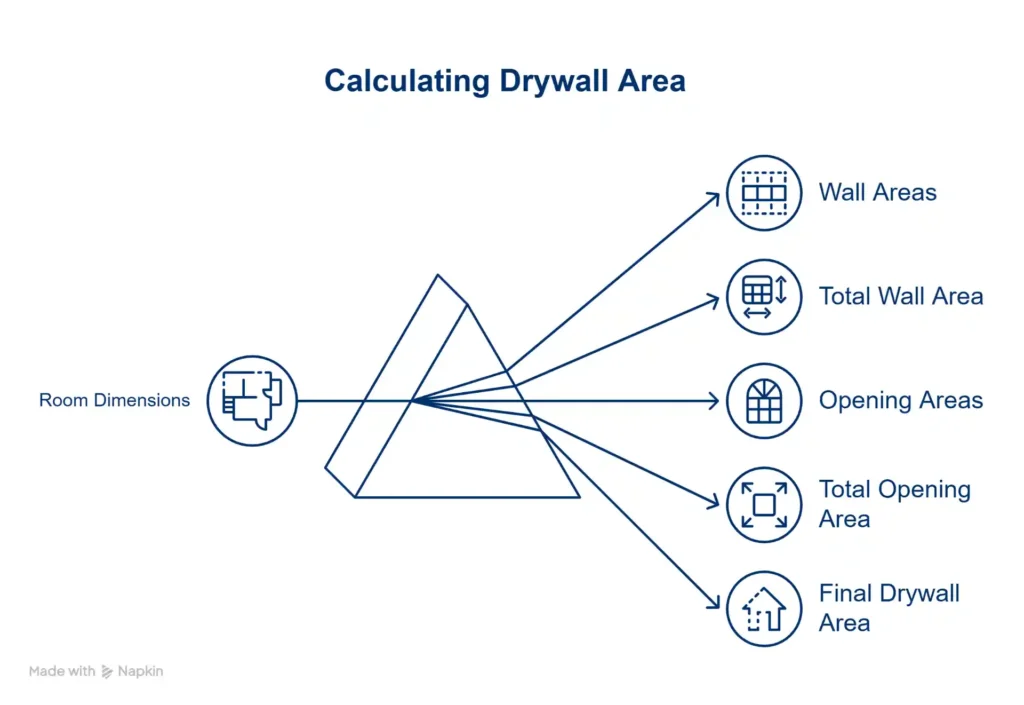

Calculate Drywall Area

Exploring the art of drywall calculation provides a strategic way towards the bottom line. A precise calculation lowers the likelihood of overestimation and underestimation, ultimately leading to the overall efficiency of the project. Estimate the area in such a way:

Area of drywall = Height × width (of each wall)

Measure the openings of the drywall and subtract that area from the total area.

Tapping into technology simplifies the process to get accurate results like laser distance measurer, digital tape measure, mobile apps, estimating software and LIDAR-equipped devices, etc.

Example:

Let’s say you have a room with four walls:

- Wall 1: Height = 8 feet, Width = 12 feet, Area = 96 square feet

- Wall 2: Height = 8 feet, Width = 10 feet, Area = 80 square feet

- Wall 3: Height = 8 feet, Width = 12 feet, Area = 96 square feet

- Wall 4: Height = 8 feet, Width = 10 feet, Area = 80 square feet

Total Wall Area = 96 + 80 + 96 + 80 = 352 square feet

Now, let’s say there’s one door and one window:

- Door: Height = 7 feet, Width = 3 feet, Area = 21 square feet

- Window: Height = 4 feet, Width = 3 feet, Area = 12 square feet

Total Opening Area = 21 + 12 = 33 square feet

Final Drywall Area = 352 – 33 = 319 square feet

Consider Drywall Thickness

The thickness of drywall is the most influential figure to determine the total material cost for drywall estimation. Choose an appropriate thickness specific to the project. Typically, ½” is practiced for home walls and ceilings and ⅝” for commercial houses that require soundproofing or fire rating environment. Integrating the advanced takeoff methods refines the procurement process to reduce the errors, driving the profitability up.

Account for Trim and Edge Conditions

It is where the planning meets the professionalism to create a seamless surface of drywall. During drywall takeoff calculations, analyzing the trim materials ( i.e. corner beads, baseboards) and edge conditions ( like finishes or drywall tape) saves you from financial surprises down the line. Consider factors like material selection, labor and complexity, waste factor and specific work when accounting the trim and edge conditions. A careful analysis helps you to make informed decisions for cost-effective projects.

Measure Accurately

Accuracy is determined as the touchstone to ensure profitability, stability and productivity of drywall takeoff. An accurate estimation is not only required to ensure budget control but also for bidding and planning for the successful execution of the project. Although it is a crucial aspect of the project, mindful planning and understanding can steer the project towards accuracy.

Use Digital Takeoff Tools

It is worthwhile to invest in digital takeoff tools to avoid time constraints and cost inefficiency. In the advanced technical support, incorporate digital takeoff tools to minimize the miscalculations at every estimating step. For instance, CostX, PlanSwift, Stack estimating, ProEst, and many more ensure bulletproof accuracy to boost productivity and profitability.

Estimate Installation Time

The completion of projects within standard timeframes reflects the reliability and professionalism of estimators. Account for all the factors to estimate the installation time for the project effectively. Deviating from the allotted timeline hurts the baseline of the project by influencing the cost factors like labor cost. It is necessary to ensure a robust takeoff process for drywall.

Factor in Material Waste

It is a cautious portion of the project to streamline the effectiveness of the project for profit margins. Overlooking or underlooking both can cause significant changes in the working process. Balancing this factor to set the financial stability of the project by careful planning and analysis of the project requirements.

Account for Labor Cost

Labor cost shares a huge portion of the overall budget for drywall. Labor cost isn’t just a number — it’s a reflection of the time, skill, and complexity involved. Ignoring it or estimating it poorly can lead to major cost overruns or failed bids.

Include Additional Labor Tasks

Takeoff outcomes are highly affected by the additional tasks that include taping, mudding, and finishing. Employing them in the estimate allows a better stream of the project without the emergence of potential risks. Compromising such tasks can skew the projected profit margins to cover them in the budget.

💡 Note: Every successful build starts with precise planning.

Let our drywall takeoff services handle the numbers so you can focus on results.

Contact us today to get your accurate estimate!

How do you account for any irregularities when doing a drywall takeoff?

While performing a drywall takeoff, it is mandatory to account for irregularities that may arise anywhere in the architectural design, measurements, calculations and material assumptions for the project. For example, unit conversion errors, wastage miscalculations, underlooking or overlooking special requirements, etc. Considering these irregularities can overcome the costly overruns and delays. Here are some essential steps to follow when conducting a drywall takeoff to tackle the irregularities:

- Site inspection: Conduct a site visit to get a better picture of the working area. Observe framing alignment, surface irregularities, ceiling joist anomalies, moisture and mold issues, mechanical and electrical obstructions and many more to install drywall accurately.

- Analyse architectural blueprints: Overview the architectural drawings to observe the deep aspects that may be missed during the site visit, such as wall angles, rounded corners and recessed areas..

- Leverage digital takeoff software: Incorporate the digital takeoff tools to identify the and measure irregularities by tracking the digital drawings. These tools offer you an accurate estimate in a quick note to optimize the estimating process.

- Identify the waste factor: A variable cost factor that depends upon the complexity of drywall installation. Ensure the contribution of the waste factor to the overall cost to avoid any unpredictable delays or errors.

How do you determine the number of drywall sheets needed for a job?

Once you quantify the drywall sheets, you will perform budget planning, project scheduling, material procurement, labor needs and waste management in a better way. The right and accurate calculation is crucial to leading a budget-friendly lifecycle of a project. It is a multifactorial aspect of drywall takeoff. Let’s outline the factors to calculate it efficiently:

1. Measure the Area

Take the measurements of space where drywall is to be installed, such as walls and ceilings. For regular shapes, calculate the area by multiplying length and width in square footage. On the other hand, portionize the area into different sections and calculate the area for each if it is an irregularly shaped area.

2. Account for Waste

When it comes to doing a takeoff for drywall, adding the waste factor becomes a most considerable factor to complete the project efficiently. When you order an exact amount of drywall sheets, it leads to the scarcity of material as they break during transportation, handling, installation and cutting. To cope with such discrepancy, add the waste factor of approximately 10% to the total square footage of the drywall sheets.

3. Consider Drywall Size

In the market, drywall sheets are available in standard sizes, such as 4 feet by 8 feet or 4 feet by 12 feet. Opt for the right option that suits the dimensions of the installation area. It ensures cost-effectiveness by reducing the waste factor in mounting the drywall. For instance, if you want to construct drywall for a ceiling with 8-feett by 12-feet dimensions, select the sheet with 4 feet by 8 feet. There is a need for 3 drywall sheets to cover the ceiling area.

4. Calculate the Number of Sheets

Following the selection of drywall sheets of appropriate size, it turns to determine the required quantity for an installation area. For this purpose, divide the total square footage by the area covered by one sheet.

Let’s continue the previous example: the total square footage was (8 ×12 = 96 feet). Divide it by the size of the sheet (4 × 8 = 32 feet). There is a need for 3 drywall sheets to cover the ceiling area of 96 feet.

Must ensure the addition of a waste factor in this calculation to deal with unforeseen circumstances or errors during installation.

People who read this also read this: How to Estimate Electrical Work [7 Easy Steps]

What type of tools are needed to do a drywall takeoff?

Every domain of the construction field requires targeted tools and equipment for accurate and efficient measurement. Let’s have a look at the tools that are needed to estimate the drywall takeoff:

- Measuring tape: Select a reliable measuring tape with proper calibration for accurate calculation of the dimensions of the area where the drywall is to be mounted.

- Calculator: It is the prime component to fasten the calculation for the drywall process. It is employed to measure the quantities of drywall sheets, screws, joint compounds, corner beads and other materials for reducing manual errors.

- Plan viewer software: Incorporate plan viewer software to measure the parameters by digital takeoff. It speeds up the takeoff process by taking measurements such as linear, area, and count measures.

- Estimating software: This is the most valuable approach to generate qualified and accurate estimates quickly. Select the right estimating software with maximum features such as customizing materials, report generation and integration with other effective tools to streamline the takeoff process that parallels your project needs. Let the estimating software crunch you a meticulous estimate for drywall.

- Digital camera or smartphone: Estimators use the digital camera or smartphone to take photos for visual references, remote collaboration, and to keep a record in case any issues arise during estimation. Any capturing tools must be equipped with high resolution to ensure the proficiency of the project.

Common Mistakes & How to Avoid Them

| Mistake | Impact | How to Avoid |

| Skipping openings or subtracting incorrectly | Over-ordering, excess cost | Use checklist and cross-check openings with drawings/site. |

| Not accounting for waste | Stock shortages or excess | Apply project-specific waste % (5-15% based on complexity). |

| Choosing wrong sheet size/thickness | Extra seams, higher labour, wrong material | Review specs, pick sheet length suited to wall height. |

| Ignoring trim/edge/finish complexity | Under-estimated labour & materials | Include corner beads, control joints, finish level in takeoff. |

| Manual measurement errors | Inaccurate quantities | Use software and cross-check manually selected critical areas. |

Conclusion

How to do takeoff for drywall is an artful and mindful task to design a fail-proof estimate. Careful planning and scheduling by factoring all the deliverables of the project allows the estimators to make data-driven decisions.

At Unity Estimating, we integrate the drywall takeoff process with advanced technical strategies that drive your project towards productivity and profitability. A professional estimator like us optimizes your estimating process in multiple ways by understanding the scope of the project clearly and carefully. At Unity Estimating, we help you reach the estimating software for the generation of well-executed estimates to achieve success in your endeavours.

Frequently Asked Questions (FAQ)

Q1: How many drywall sheets do I need for a 1,000 sq ft room?

A1: If using 4×8 sheets (32 sq ft each), 1,000 ÷ 32 ≈ 31.3 → round up to 32 sheets, then add waste factor (≈10%) → ~35 sheets.

Q2: What waste factor should I allow for drywall takeoff?

A2: Standard jobs: 5-10%. Complex jobs (curves, fire/sound walls, many openings): 10-15% or more.

Q3: What thickness of drywall should I use?

A3: ½″ is common for standard interior walls. Use ⅝″ for fire-rated, soundproof, or commercial projects.

Q4: Which software is best for drywall takeoff?

A4: There’s no one “best” tool; look for features: digital measuring, plan import, material database, labour integration. Popular options: PlanSwift, Bluebeam, ProEst, Togal.AI.

Q5: Can I use metric units instead of imperial?

A5: Yes—convert all measurements into square metres (m²) and sheet sizes accordingly (e.g., 1.22 m × 2.44 m sheet). Ensure your local suppliers and labour units align with metric.